Helpful guide on installing a cylinder head

Installing a new or remanufactured cylinder head on an engine is relatively simple and requires no advanced skills. This Foley Tech Tip, one of an ongoing series, provides a guide to cylinder head installation.

Installing the Head

Carefully check the head gasket to ensure it is correct and not covering coolant holes. Place the new gasket onto the cylinder block, checking for proper alignment. Lay the head down on top of the gasket. To avoid altering torque readings clean all bolt holes. Use clean but not pre-lubed bolts or studs.

Torque Sequence

Using a torque wrench, carefully tighten the fasteners in a circular pattern starting in the center and working out to the edges. Consult Foley Tech Tip #10, Torque Values and Valve Settings, for recommended torque values. Retorque the head after the initial warm up and again after 50 hours of operation. Adjust the valves at the same intervals.

Some diesel engines including Deutz, Deere, and Perkins, now have torque to yield head bolts. We have Workshop Manuals in stock and ready to ship for Deutz and Perkins engines and carry head bolts too.

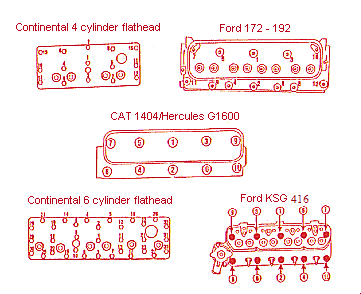

Illustrated below are the recommended torque patterns for five common gas industrial engines, the Continental F163 and F245, the Cat 1404/Hercules G1600, the Ford 172/192, and the Ford KSG 416.

Please call us with your comments or suggestions. We take tech support seriously and want to advance the knowledge base in our field.