This Dr. Diesel™ Tech Tip, one of now more than 200 we publish for the industrial engine community, discusses how to identify the connecting rods in a Perkins 1000 Series engine. This Tech Tip follows in the path of others we have published that were concerned with Perkins connecting rods including

- Tech Tip #76: The Nuts and Bolts of Con Rod Reconditioning

- Tech Tip #6: Diesel Rod Reconditioning.

The Perkins 1000 Series engine replaced the familiar Perkins 4.236 and Perkins 6.354 Series engines in the mid-1990s. It is easily distinguishable from the earlier 4.236 and 6.354 by the gear driven water pump mounted off to one side on the front of the engine versus the belt driven center mount water pump on the earlier engine. Rebuilding a 1000 Series is no more difficult than rebuilding a 4.236 or a 6.354. Some of the Perkins 1000 Series, typically the naturally aspirated, non-turbocharged models, don’t even have liners just parent-bore cylinders which are re-machined at overhaul time.

The Perkins 1000 Series engine replaced the familiar Perkins 4.236 and Perkins 6.354 Series engines in the mid-1990s. It is easily distinguishable from the earlier 4.236 and 6.354 by the gear driven water pump mounted off to one side on the front of the engine versus the belt driven center mount water pump on the earlier engine. Rebuilding a 1000 Series is no more difficult than rebuilding a 4.236 or a 6.354. Some of the Perkins 1000 Series, typically the naturally aspirated, non-turbocharged models, don’t even have liners just parent-bore cylinders which are re-machined at overhaul time.

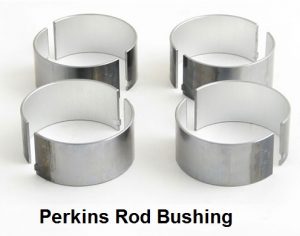

One troublesome area though is the connecting rods and bearings. Early 1000 Series engines use the familiar serrated or “manufactured” connecting rods and later engines used “fractured” rods. It is important that rebuilders accurately identify which connecting rod they have. Different bearings are used depending upon if the rods are serrated or fractured.

One troublesome area though is the connecting rods and bearings. Early 1000 Series engines use the familiar serrated or “manufactured” connecting rods and later engines used “fractured” rods. It is important that rebuilders accurately identify which connecting rod they have. Different bearings are used depending upon if the rods are serrated or fractured.

Unfortunately, the engine build list (for example, AQ 12345) and even the complete engine serial number (for example, AQ 12345U1234567S) sometime don’t accurately tell which rods are in the engine. Moreover, over time the engine’s connecting rods may have been changed or updated to the more modern fractured style, but here is how to tell the difference.

Rod Bolts vs. Capscrews

Rod Bolts vs. Capscrews

The earlier connecting rods have conventional rod bolts with washers, plus the bearings themselves have a locking tang. The later serrated rods which as noted above take different bearings have capscrews with no washers and no locking tang. Simple as that: bolts with washers with bearing tangs or capscrews without tangs on the bearings.