This Tech Tip is the newest one in a number we publish for the industrial community. It focuses on properly installing Deutz and Perkins cylinder heads. See

- Tech Tip #30: Installing a Cylinder Head or

- Tech Tip #68: Foley Engines Head Installation Checklist

for more information on installing your cylinder head on your Deutz or Perkins engine.

1) Hash Marks Count

1) Hash Marks Count

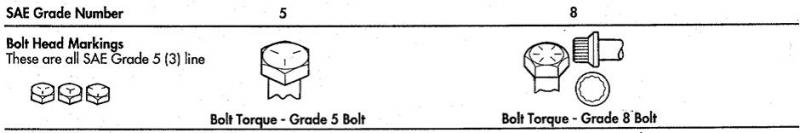

As a general rule, Dr. Diesel™ says the more hash marks on the top of a bolt, the higher the grade. Grade 5 bolts have three hash marks on top and Grade 8 bolts have five hash marks. The chart below shows how to tell a Grade 5 bolt from a Grade 8 bolt.

2) Torque Values: Part One

Modern diesels such as those manufactured by Deutz and Perkins often have a very complicated three or four head bolt tightening process which involves tightening the bolts sequentially to specific torque values and a final step consisting of tightening the bolts to a specific angle. We stock and have ready to ship Perkins and Deutz Workshop Manuals with detailed information on the specific head torque values and sequences for specific Deutz and Perkins engines. Please call us toll free at 800.233.6539 to order. In a hurry? With an order for a Deutz or Perkins Manual we will photocopy the relevant pages and fax them to you.

3) Torque Values: Part Two

We have listed below torque values by size of bolts for bolts without lubricant applied. Use a reduced torque value if the bolt has been lubricated. For help with installing cylinder heads and valves on your Perkins, Deutz, or other industrial engine, take a look at Tech Tip #10: Torque Values and Valve Settings and Tech Tip #30: Installing a Cylinder Head for more information.

4) Deutz 912 Cylinder Head Torque Considerations

4) Deutz 912 Cylinder Head Torque Considerations

We recently ran into an odd situation with one of our customers. He was installing a set of new Deutz heads (at $199 each for new 912 heads from Foley why rebuild?) on his F6L912 Deutz diesel. Besides new heads, he has bought from us new 912 head bolts (Deutz Part Number 415 1904) and washers (Deutz Part Number 337 1666). He was tightening down the head bolts in the correct, sequential, pattern until at around 80ft/lb the torque wrench moved like it was broken and all resistance was gone. Lo and behold the new washers had stuck to the bolts and the 912 head bolts and washers turned together as one.

At some point the washers loosened their grip on the bolts and this created this unusual feeling. The solution is simple. Both sides of the washer should be coated with engine assembly lube. Our shop people use a mixture of SAE30 motor oil and STP as assembly lube with good results. We’ve been tempted to market it as some special engine assembly lubricant but Dr. Diesel™ says we could help more people by just giving out the ingredients. Ya gotta love our Dr. Diesel!

At some point the washers loosened their grip on the bolts and this created this unusual feeling. The solution is simple. Both sides of the washer should be coated with engine assembly lube. Our shop people use a mixture of SAE30 motor oil and STP as assembly lube with good results. We’ve been tempted to market it as some special engine assembly lubricant but Dr. Diesel™ says we could help more people by just giving out the ingredients. Ya gotta love our Dr. Diesel!

5) 51 Bolt Torque Specs by Size and Grade

The chart below is presented showing bolt torque value by size. We wish to thank the AERA for preparing this chart.

|

Bolt Torque – Grade 5

|

Bolt Torque – Grade 8

|

||||||||

|

Body Size

|

Cast Iron (Nm)

|

Cast Iron (Ft/lb)

|

Alum (Nm)

|

Alum (Ft/lb)

|

Body Size>

|

Cast Iron (Nm)

|

Cast Iron (Ft/lb)

|

Alum (Nm)

|

Alum (Ft/lb)

|

|

¼” 20

|

9

|

7

|

8

|

6

|

¼” 20

|

15

|

11

|

12

|

9

|

|

¼” 28

|

12

|

9

|

9

|

7

|

¼” 28

|

18

|

13

|

14

|

10

|

|

5/16” 18

|

2

|

15

|

16

|

12

|

5/16” 18

|

30

|

22

|

24

|

18

|

|

5/16” 24

|

23

|

17

|

19

|

14

|

5/16” 24

|

33

|

24

|

25

|

19<

|

|

3/8” 16

|

40

|

30

|

25

|

20

|

3/8” 16

|

55

|

40

|

40

|

30

|

|

3/8” 24

|

40

|

30

|

35

|

25

|

3/8” 24

|

>60

|

45

|

45

|

35

|

|

7/16” 14

|

60

|

45

|

>45

|

35

|

7/16” 14

|

90

|

65

|

65

|

50

|

|

7/16” 20

|

65

|

50

|

55

|

40

|

7/16” 20

|

95

|

70

|

75

|

55

|

|

½” 13

|

95

|

70

|

75

|

>55

|

½” 13

|

130

|

95

|

100

|

75

|

|

½” 20

|

100

|

75

|

80

|

60

|

½” 20

|

150

|

110

|

120

|

90

|

|

9/16” 12

|

135

|

100

|

110

|

80

|

9/16” 12

|

190

|

140

|

150

|

110

|

|

9/16” 18

|

150

|

110

|

115

|

80

|

9/16” 18

|

210

|

155

|

170

|

125

|

|

5/8” 11

|

180

|

135

|

150

|

110

|

5/8” 11

|

255

|

190

|

205

|

150

|

|

5/8” 18

|

210

|

155

|

160

|

120

|

5/8” 18

|

>590

|

15

|

230

|

170

|

|

>¾” 10

|

325

|

240

|

255

|

190

|

¾” 10

|

460

|

340

|

365

|

270

|

|

¾” 16

|

365

|

270

|

285

|

210

|

¾” 16

|

515

|

380

|

410

|

300<

|

|

7/8” 9

|

490

|

360

|

380

|

280

|

7/8” 9

|

745

|

550

|

600

|

440

|

|

7/8” 14

|

530

|

390

|

420

|

310

|

7/8” 14>

|

825

|

610

|

660

|

490

|

|

1” 8

|

720

|

530

|

570

|

420

|

1” 8

|

1100

|

820

|

890

|

660

|

|

1” 14

|

800

|

590

|

650

|

480

|

1” 14

|

1200

|

890

|

960

|

710

|